Your Lean Manufacturing Implementation Solution

Maximize productivity. Minimize waste. Exceed your Gross Line Yield.

Make Lean Manufacturing Actionable for Your Teams

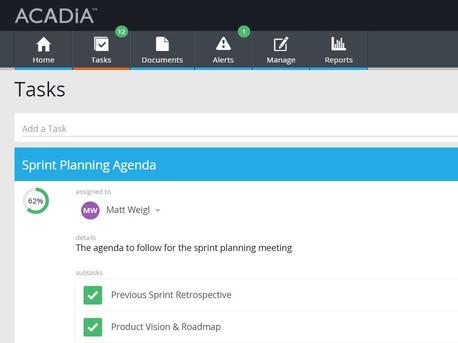

Acadia helps you reduce variation and maintain continuity through consistent procedure execution on our Connected Worker Platform

- Single source of truth for procedures and reaction plans

- Digital work instructions to ensure compliance

- Multi-media job aids to support accurate execution

- Identify gaps in employee skills and productivity

Acadia makes it easy to execute lean manufacturing principles. See how one of our clients exceeded gross line yield goals in 6 months.

Lean Manufacturing Software Across Your Entire Process

Leverage digital work instructions to provide a single source of truth, accessible to employees throughout their entire journey, from onboarding and training to daily task execution.

- Guide training with step-by-step, role-based work instructions

- Provide support at the point of use with multi-media job aids

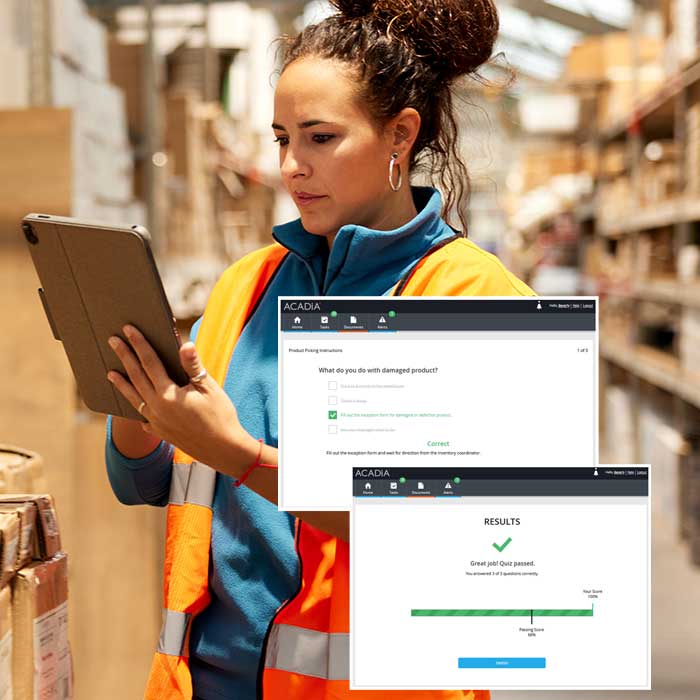

- Reinforce key points and gauge comprehension with quizzing

- Measure individual compliance easily at scale

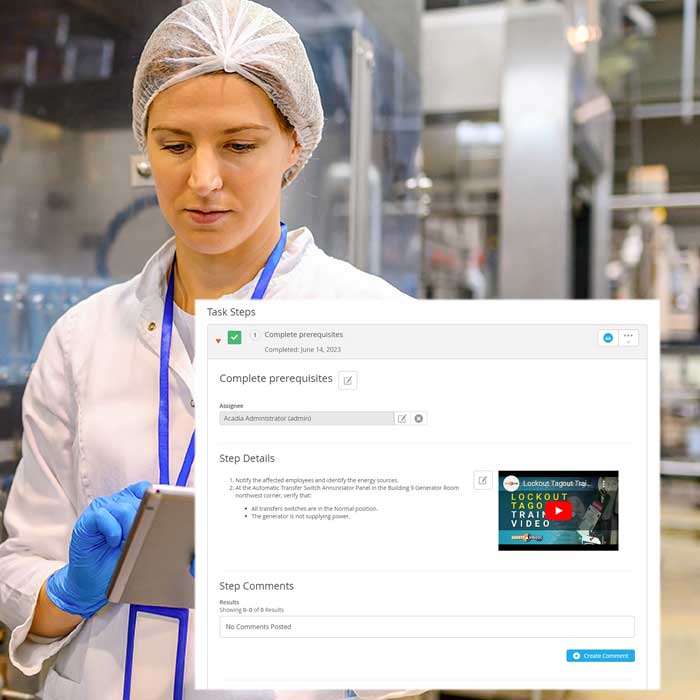

Our digital work instructions put your One Best Way processes right in the hands of your frontline teams from the start, allowing them to become ingrained habits for employees. Applied as a lean manufacturing tool, this means you can:

- Make troubleshooting procedures instantly available

- Identify process improvements and deploy them digitally across your entire workforce

- Use process improvements to reduce manufacturing waste

- Reduce production downtime and workplace accidents

Capture feedback, update procedures, and introduce changes without interrupting work.

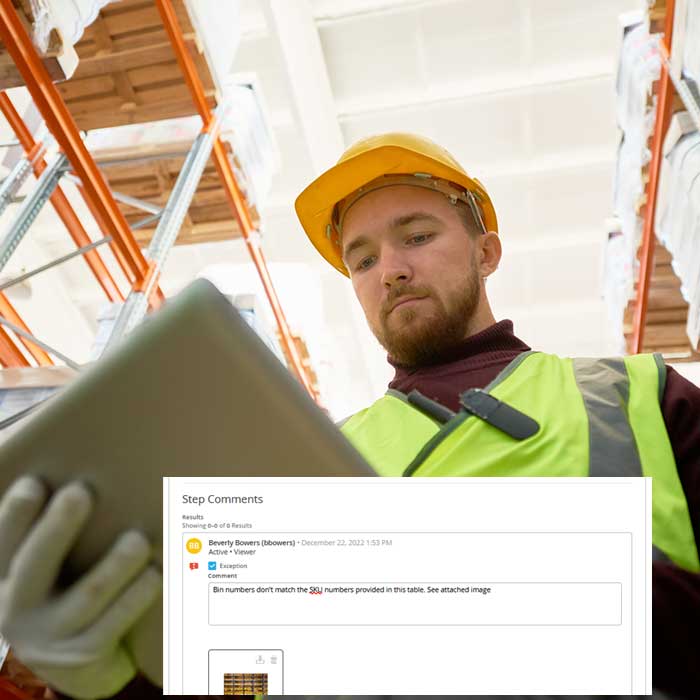

- Evaluate opportunities to improve processes by capturing relevant feedback throughout the process

- Deploy workplace improvements digitally across your entire workforce

- Ensure and measure individual compliance easily and quickly

The consistency and clarity offered by digital work instructions can enhance product quality and contributes to improved employee retention. By embracing digital work instructions as a key component of lean manufacturing:

- Ensure that employees work efficiently, safely, and in alignment with the best practices

- Drive both operational excellence and a safer, more productive workplace

- Identify workforce gaps through a skills matrix

- Create individualized career paths that align with your workforce gaps

Autonomous Lean Production at a Global Scale at AB InBev

As one of the largest beverage and leading beer producers, AB InBev recognizes the importance of maintaining quality and consistency across their global production line. Since 2016, AB InBev has harnessed the power of Acadia to embrace lean manufacturing principles and foster autonomous teams.

To gain insight into how Acadia supports lean manufacturing at AB InBev, watch this brief video featuring Global Product Owner Denise Channer.

More Acadia Client Results

Let’s Talk Lean Manufacturing

"*" indicates required fields