Employee Retention Starts Day 1: How to Improve Efficiency & Engagement

Improve employee retention and efficiency with 4 proven training strategies.

- Manufacturing is struggling to find skilled workers with the mass retirement of baby boomers and a labor shortage that could continue through 2030.

- The tightness of the job market puts the power in the hands of the employees making retention even more critical.

- 96% of employees are more likely to stay if they feel confident doing their work.

- On-the-job training, confirming comprehension, and engagement help you bring on new employees and keep them for the long-term.

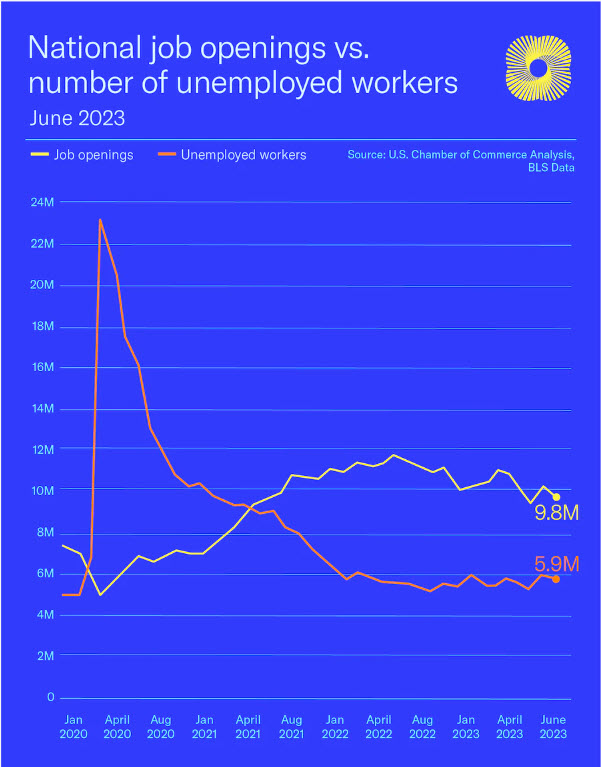

“The worker shortage is real — and it’s getting worse by the day,” that’s how US Chamber of Commerce President and CEO Suzanne Clark began her announcement. That was March 2021. The organization showed there were a record 8.1 million job openings in the United States at the time and about half as many available workers for every open job.1 Today, that number is up to 9.8 million with 5.9 million people unemployed.2

This news comes as no surprise to anyone trying to fill an open position or retain employees in the current labor market.

For factory, warehouse, and other blue-collar jobs, the labor shortage could continue through 2030.3 At the height of the pandemic, more than 30 million U.S. workers were unemployed and they are taking their time returning to the workforce.2

The lack of frontline operators didn’t start with the pandemic, however. Several of Acadia’s manufacturing customers have been dealing with the fallout from the mass retirement of baby boomers for at least the last five years. But the pandemic has certainly exacerbated an already challenging trend. Even executives are spending time on the plant floor to fill the gap.6

The roots of the $1T problem7 are multifaceted.

Plants are struggling to find skilled workers for specialized roles and others are having trouble hiring entry-level positions. Beyond the mass exodus of older workers, younger generations don’t see the same value in these jobs as their parents did.8

At the same time, the tightness of the job market is creating tremendous competition. It’s never been easier for an employee to quit his job at one plant, walk across the street, and get hired at another. And in many cases, it’s literally that easy.

Then there’s the utter waste of time and resources spent onboarding and training new team members who leave after a couple of weeks or months. That should send chills up the spine of any Lean practitioner.9 Talk about wasteful practices and non-value-added work!

What all this boils down to is retention has become an even more urgent focus for companies already struggling to fill open positions. And retention starts on day one.

On-the-job Training Creates Confident Employees

There are many reasons employees decide to leave, but the one we hear most often from our customers boils down to lack of confidence. In fact, 96% of employees say they’re more likely to stay if they feel confident doing their work.10 That’s particularly true in a dangerous industrial environment. If they don’t feel comfortable, they won’t stay. It’s as simple as that.

Unfortunately, traditional training methods don’t instill much confidence, quite the opposite. If the bulk of your training takes place in a classroom or in a LMS at a desktop computer, your new hires are only retaining about 20% of what they learn.

That’s why on-the-job training is perceived by line managers and HR professionals alike as the most effective way to train new or job changing employees. But its application is spotty at best. With shoulder-to-shoulder training, there’s no way to know how much or how little a new hire is learning. By the time you figure it out, they may have left or made a costly mistake.

By contrast, consider the onboarding process at a major beverage manufacturer who uses Acadia for new hire training. Their process begins on the plant floor – following One Best Way work instructions in the form of a task list, on a mobile device. The work instructions are simple and clear. They can be followed step-by-step. They’re accompanied by videos, images, and other job aids.

Our customer’s new hires see experienced team members using the work instructions as part of their workflow as well. It bolsters their confidence to know they’ll have access to the same tools once training is complete. It also becomes the expectation for the new employee that they will continue to follow the One Best Way processes.

Strong onboarding and training help create confident team members. But, even the best training programs will fail some new hires. And it’s important to identify and help those who slip through the cracks.

Confirming Comprehension

Sometimes, we don’t know an employee is struggling until there’s a safety incident, a quality recall, or a scrapped batch.

To avoid these mistakes and to help further cement best practices with new hires, we recommend incorporating quizzing and evaluations into your training protocols.

Quizzing on information that’s critical to the success of a procedure or workflow can help you quickly identify the team members who need additional training. What’s even more helpful, is quizzing helps embed critical information in their long-term memory, making it easier and faster to recall.

More extensive evaluations work similarly and can be used to assess team members reaching critical milestones in their training or career paths.

An Acadia customer that specializes in outsourced truck yard management, requires new employees to follow a series of safety steps before getting behind the wheel. The steps are designed to protect the driver and the customer’s property, so it’s critical that everyone adopt the process as second nature.

To help with this, our customer follows up all of their training sessions with quizzes on their safety protocol. Nobody gets to drive until they pass. As a result, the company has less accidents, fewer insurance claims and happier customers.

Training and knowledge comprehension are great for bringing on new team members. To keep them after the first few months, engagement needs to become the long-term focus.

Engagement, engagement, engagement

Ask most business leaders what they think it takes to retain employees, and you’ll hear a lot about better pay, time off, and other benefits. While those are important factors, what seems to matter more is employee engagement.

Highly engaged employees are less likely to leave their company. They generate more revenue and profit for their companies than competitors with lower engagement. They’re also simply more likely to show up to work.11

But engagement is one of those vague terms that feels ridiculously difficult to achieve and even harder to measure. Something that’s loftily talked about at HR conferences, but can’t be achieved in real life with thousands of frontline operators under the gun to meet production goals.

Thankfully, engagement doesn’t mean throwing parties every week or having heart-to-heart conversations with each of your team members about their feelings.

We’ve already described the importance of helping employees feel confident in their work. That’s the first step of engagement. The second step is making them feel part of the process, including listening to their improvement ideas and incorporating those into workflow.

In Acadia, feedback is part of workflow. Team members can provide feedback on the value and accuracy of every document in the system. They can also provide feedback as part of completing tasks. By capturing feedback during the nitty-gritty of day-to-day work, you capture the things that can really help you improve the process. Just make sure you recognize the team members who helped improve the process. A little bit of recognition goes a long way toward engagement.

An Acadia manufacturing customer is putting feedback to work both to engage and retain employees and to make improvements in its plants. In one example, a packaging machine with a worn part was creating frequent jams, but the plant manager wasn’t aware. Each jam meant the machine had to be shut down, cleared and restarted, wasting both material and time. The employees didn’t want to deal with the jams, but there wasn’t a clear method to escalate the issue. So, they just cleared them and went on with their work.

The first day using Acadia, when provided with the means to submit feedback, the operators submitted the jamming issue and the plant manager replaced the worn part right away. Who knows how much time and money would have been saved if the team could have provided that feedback sooner?

The Cost of Sticking with the Status Quo

When someone leaves our organization, we go into “reactive mode”. We start the recruiting process, we find ways to cover shifts, we ask other team members to do more. As this process plays out, we fall further behind and risk undermining the job satisfaction of our other employees.

Trying to fix the problem using the tools that hold us back only digs us into a deeper hole. It’s possible to address these challenges at the same time we improve efficiency, quality, and safety. The best time to start is now.

If you’re curious about what employee turnover costs your business, try the ROI calculator below.

Enter your data into the model on the left-hand side of the page to see your potential savings with Acadia on the right. Calculations are based on typical Acadia client results. Click on the ▼ and ⓘ icons for additional information.

Enter Your Details

With Acadia

Calculated Current State

Sources:

- The America Works Report: Quantifying the Nation’s Workforce Crisis

- America Works Data Center | U.S. Chamber of Commerce (uschamber.com)

- Report: Record Blue-Collar Labor Shortages Will Continue Through 2030 (conference-board.org)

- U.S. factories desperate for workers, even as ranks of jobless remains high

- US manufacturing activity jumps to 3-year high in February

- Low on Workers, Manufacturers Recruit Their Executives for the Factory Floor

- American factories are desperate for workers. It’s a $1 trillion problem

- ‘The End of Loyalty’: Shock and Awe for Many American Workers

- Why “I quit” is the biggest waste

- Here’s the No. 1 reason why employees quit their jobs

- The Right Culture: Not Just About Employee Satisfaction

- What People Really Want from Onboarding

Ready to crush your goals?

"*" indicates required fields